Contract manufacturing

Contract manufacturing: flexible, high-quality & customer-oriented

Home » Contract manufacturing

HSM - Machining technology stands for pioneering precision

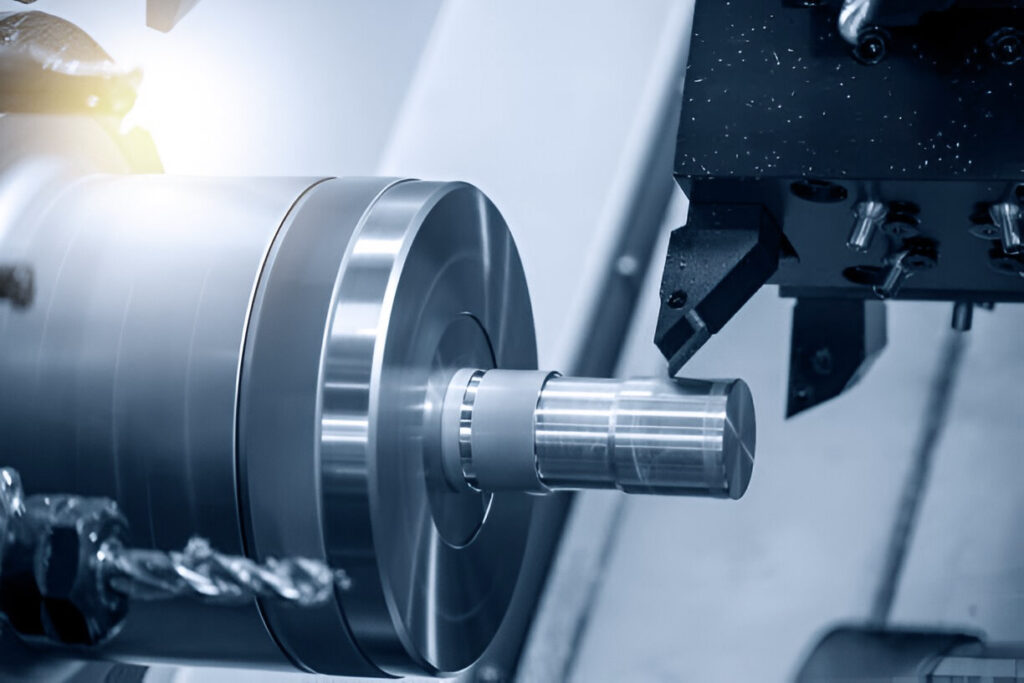

Precision and quality in CNC contract manufacturing

HSM offers comprehensive CNC contract manufacturing with a high level of vertical integration. We use state-of-the-art technology for resilient and durable products in mechanical engineering and custom-made products. We pay particular attention to high-precision drilling and turning as well as the machining of steel and aluminum. With our many years of experience and CNC-controlled machines, we offer tried-and-tested solutions for optimum results.

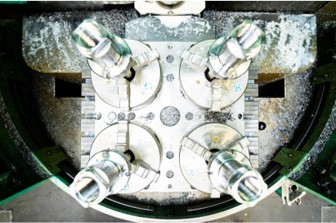

Milling machine data

Machine data Turning

Press machine data

Machine data welding

Certified processes in our welding shop

- MAG (metal active gas) DIN EN ISO 4063 135

- Stud welding with drawn arc DIN EN ISO 4063 783

- Short cycle drawn arc stud welding DIN EN ISO 4063 781

Approved base materials according to CEN ISO/TR 15608

- Material group 1

- Material group 2

- Material group 5.1

- Material group 11.1, 11.2

Available heat and surface treatments

- KTL coating

- Powder coating

- Wet painting

- Galvanizing

- Hardening/inductive hardening

Extract from our special components

- Complex welded assemblies

- Lift mast parts for industrial trucks

- Pedals for industrial trucks

- Turned & milled parts